Annunciator Panel

The annunciator panel was made from 7/8" thick hardwood. Overlapping 1/2" holes were drilled through the wood.

A half inch wood chisel was used to clean up and square off the corners of one side.

Each rectangular hole was filled with a clear 2-part liquid epoxy resin. When the resin hardened, transparent labels were applied to the front of the panel. A few tiny air bubbles and imperfections were trapped in the curing resin, due to air being expelled from the wood fibers, as the epoxy heated up. If I were to do it again, I would just pour half the amount of resin into each hole, let harden and cool, and then pour the other half. The resin can get extremely hot when curing, the more resin, the hotter it gets! But all in all, this was an experiment that worked better than I expected and will serve the purpose until a real panel can be found.

The back of the panel was painted flat black and 3/16" diameter holes were drilled to accept a 5mm LED.

Testing the LEDs and setting up individual circuits.

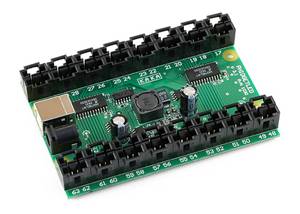

The 40 wires from the 20 LEDs connect to a Phidgets LED-64 USB controller.

PhidgetLED-64

Testing all LEDs with the caution light test button.